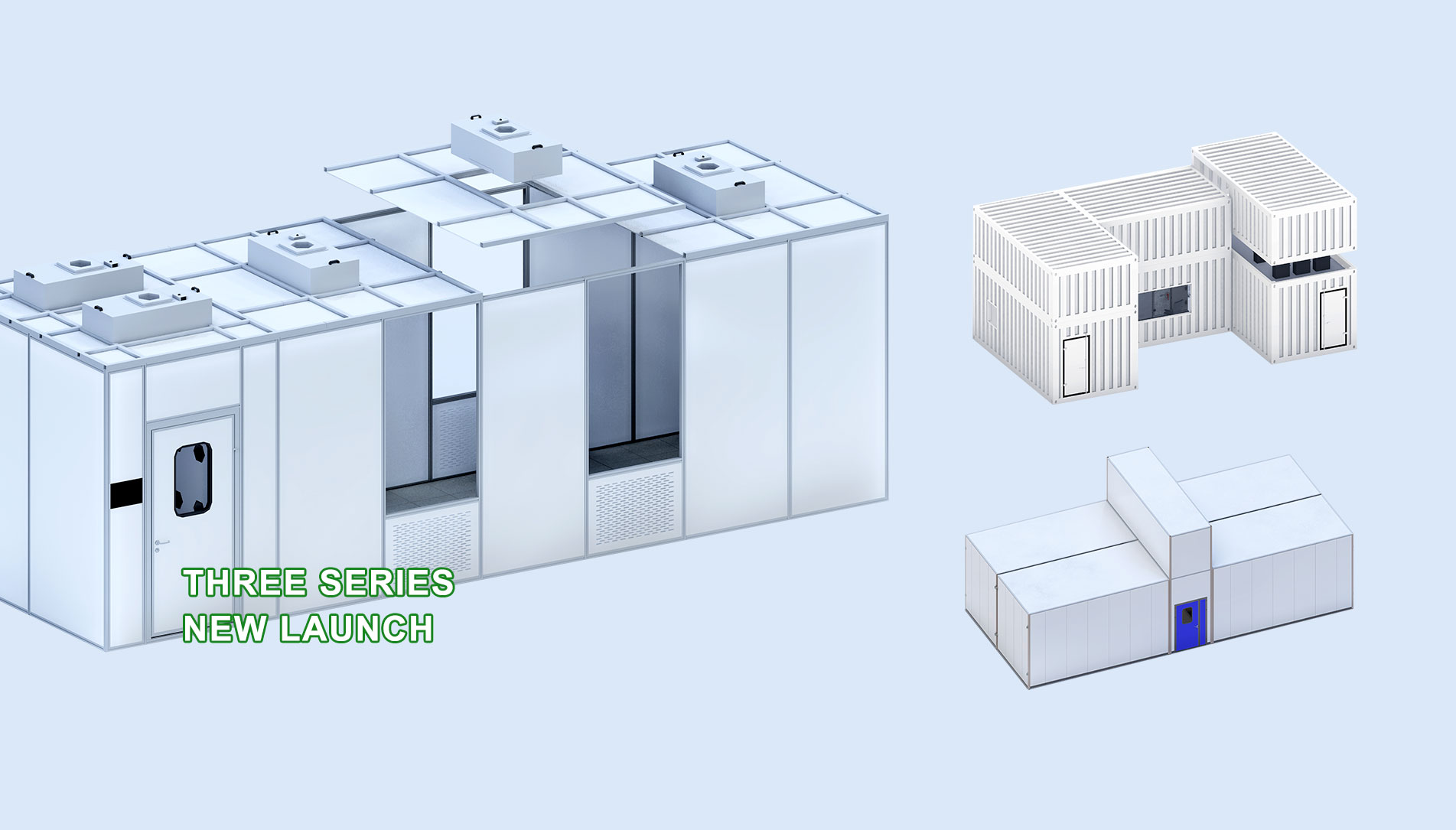

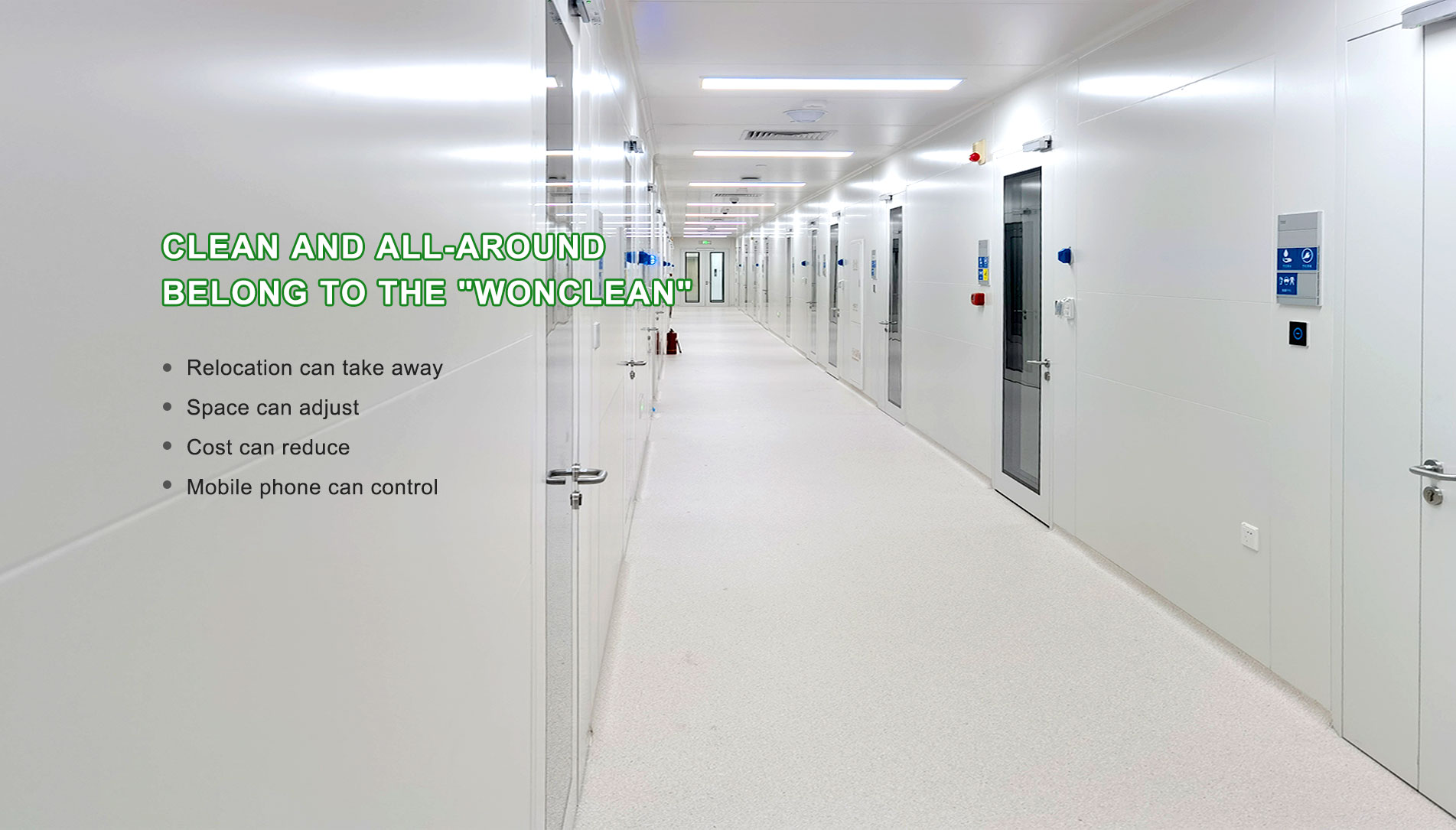

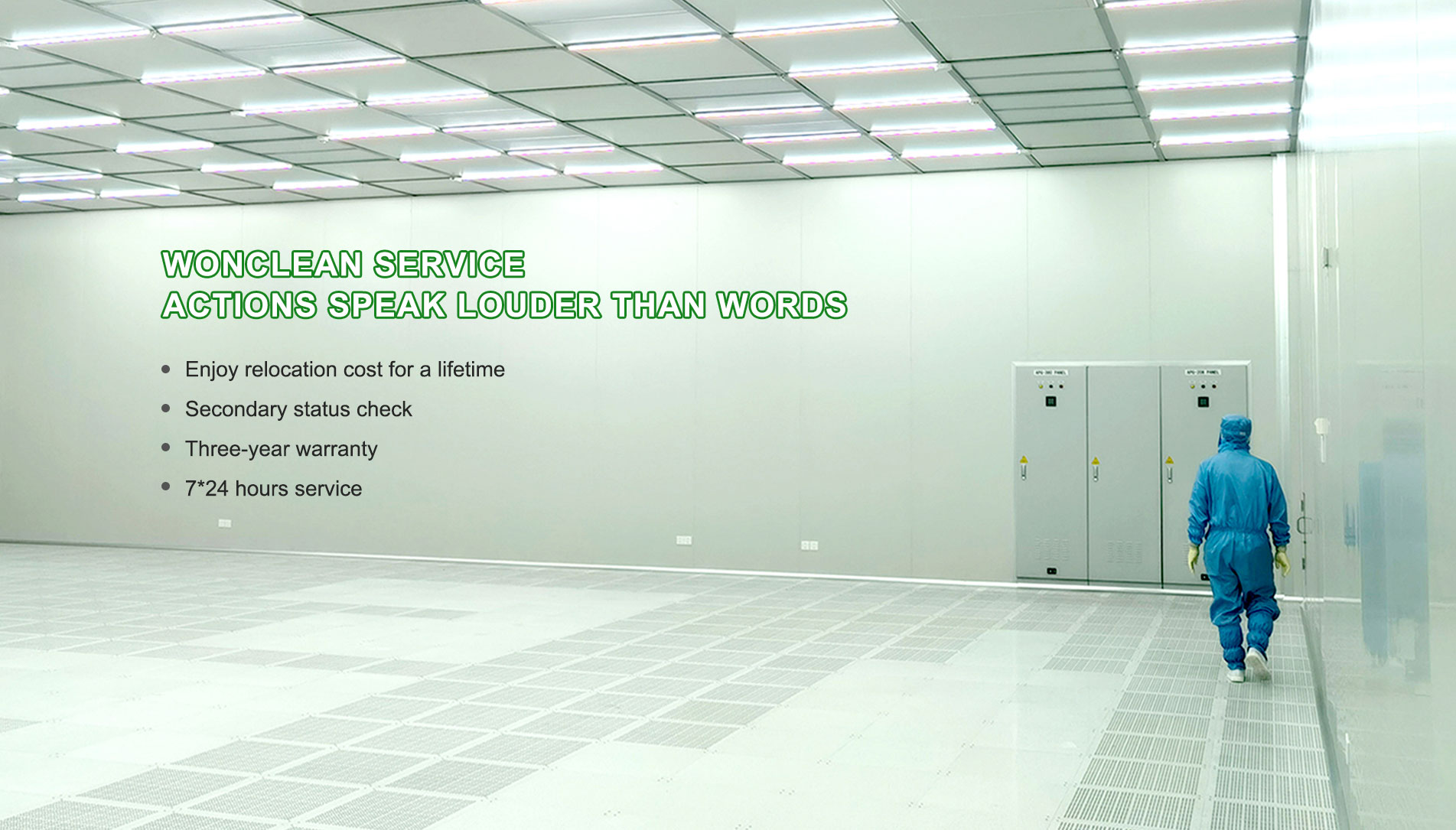

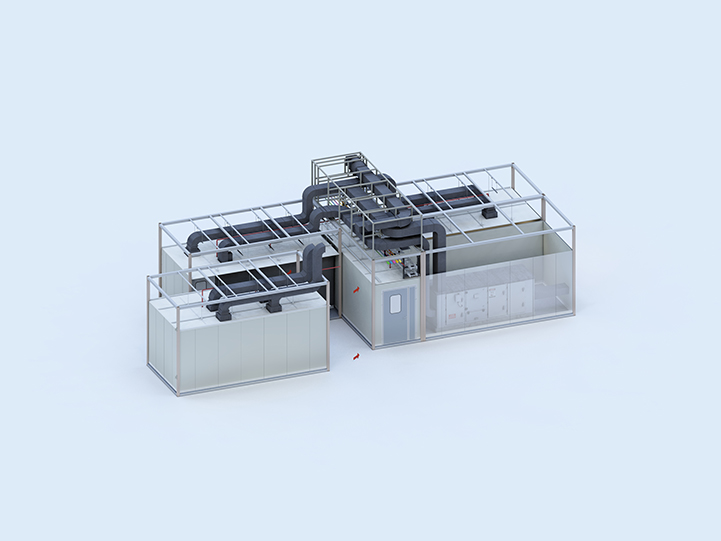

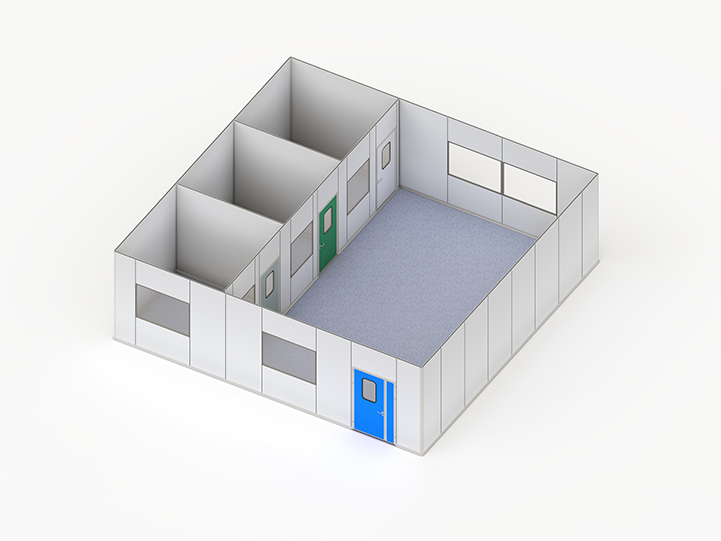

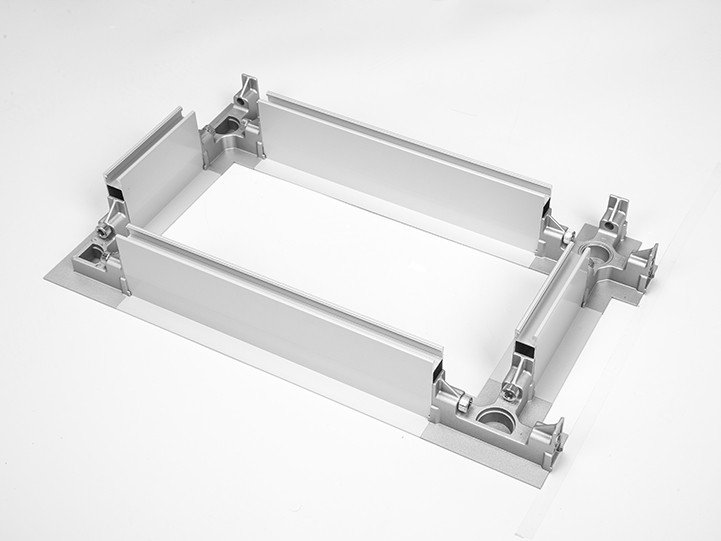

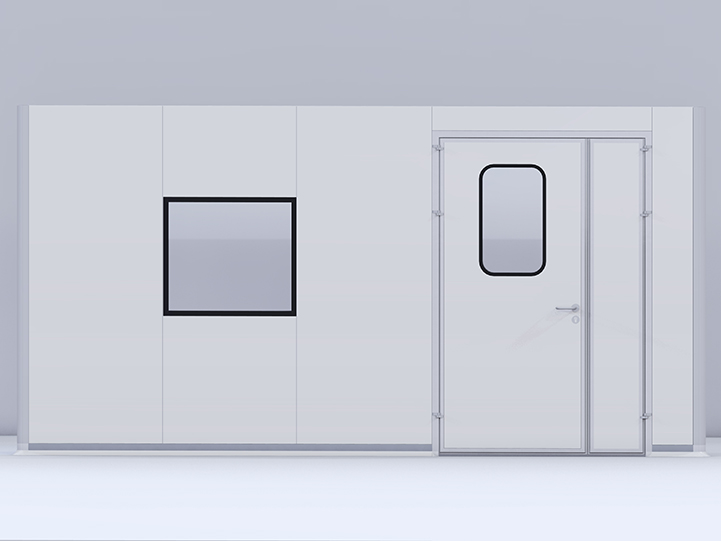

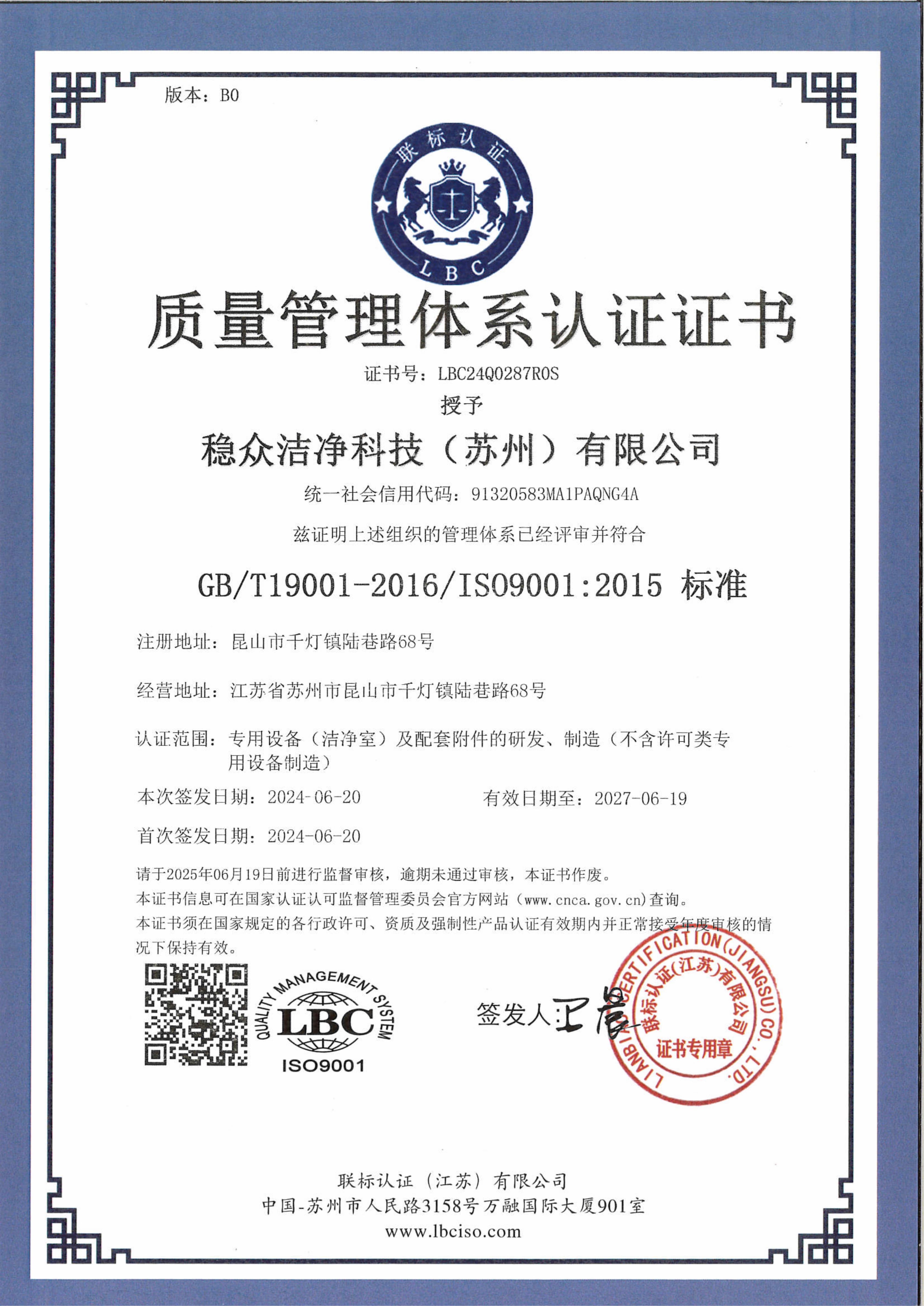

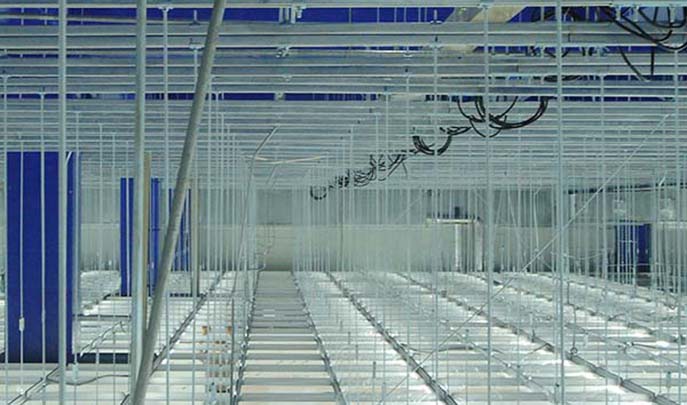

WONCLEAN: Your Premier Air Shower & Cleanroom Partner For industries where precision and cleanliness are paramount, WONCLEAN delivers excellence. As a leading air shower supplier and manufacturer of cleanroom wall panels, we provide the essential components for contamination control. Our expertise extends to complete modular laboratories and cleanrooms, including doors, windows, and integrated systems, offering a single-source solution for your critical environments. Superior Air Shower Performance As a premier air shower supplier, WONCLEAN designs equipment that sets the industry standard for decontamination. Our air showers utilize high-static pressure fans and HEPA filters to generate strong, focused airflows (22-26 m/s), effectively removing particles from personnel and goods. We offer versatile configurations—including manual/automatic doors and pass-through designs—with features like electronic interlocks, emergency stops, and programmable controls. Built with durable materials like SUS304 stainless steel, each unit ensures reliable, long-lasting performance for your critical entry points. Complete Cleanroom Ecosystem Our expertise extends far beyond air showers. WONCLEAN provides a fully integrated cleanroom ecosystem. This includes our proprietary cleanroom wall panels, known for their seamless surfaces and durability, which form the backbone of any controlled environment. We also supply all necessary ancillary products such as cleanroom doors, windows, and HVAC-integrated systems. This holistic approach, from core panels to final fixtures, ensures compatibility, simplifies procurement, and delivers a cohesive, high-performance cleanroom built to your exact specifications. End-to-End Service & Support Choosing WONCLEAN means investing in a partnership backed by exceptional service. From initial consultation and custom design using advanced 3D modeling to efficient manufacturing and strict quality control, we guide your project every step of the way. Our after-sales commitment includes a comprehensive warranty, regular on-site inspections, and 24/7 support to ensure your systems operate flawlessly. We are not just a product vendor; we are your single-source solution provider for modular laboratories, cleanrooms, and all related components. If you are looking for a reliable air shower supplier or need a complete solution for modular laboratories, cleanrooms, wall panels, doors, or windows, welcome to contact WONCLEAN.

servicio en línea

servicio en línea