In today’s precision-driven manufacturing landscape, the demand for controlled environments continues to grow. As a professional cleanroom solution provider, wonclean explains what is a cleanroom from multiple perspectives, including its characteristics, applications, and material composition. This article aims to help readers understand why cleanrooms have become essential infrastructure in advanced industries.

Scientific Definition and Core Characteristics of Cleanrooms

A cleanroom is fundamentally a controlled environment in which airborne particles, temperature, humidity, differential pressure, and airflow patterns are strictly regulated. When discussing what is a cleanroom, the emphasis is often placed on three attributes: controlled contamination, stable environmental conditions, and quantifiable management. Whether in microelectronics, pharmaceuticals, or precision testing, the goal is to protect products or processes from airborne contamination.

Key characteristics include:

-

Air cleanliness levels defined by ISO 14644, specifying particle sizes and quantities.

-

Temperature and humidity control to prevent deformation, chemical deviations, or instability during production.

-

Positive/negative pressure management to regulate airflow direction and prevent contamination inflow or outflow.

-

Continuous monitoring systems supported by sensors and automation.

What Is a Cleanroom Rating?

Cleanroom ratings define how well a controlled environment can limit airborne particles, ensuring the space meets the cleanliness levels required for sensitive processes. These ratings are developed by the International Standards Organization (ISO), a global federation that collaborates with industry groups, government agencies, and technical committees to create widely recognized performance standards and best practices. For industries relying on contamination control, these ratings serve as a universal benchmark for safety, precision, and environmental stability.

What Is an ISO 14644-1 Cleanroom?

ISO 14644-1:2015 is widely regarded as the leading international standard for building and verifying particle-controlled environments. The documentation acts as a comprehensive blueprint that guides the structural design, testing procedures, and calibration requirements needed to achieve a compliant cleanroom.

Depending on the ISO classification and the critical tasks performed inside the space, a cleanroom may require specialized features such as:

-

Isolation or containment barriers

-

Enhanced enclosure systems

-

Safe exhaust or exfiltration of hazardous vapors, aerosols, or particulates

-

Additional controls for chemical, microbiological, or particulate risks

These requirements help reduce contamination and ensure that both personnel and products remain protected.

Related:Why Cleanroom Classifications Matter for Your Facility?

Main Uses of Cleanrooms: The Hidden Infrastructure of Advanced Industries

To understand what are cleanrooms used for, industry demand must be considered. As product sizes shrink and manufacturing becomes more precise, cleanrooms have become indispensable infrastructure for many high-tech sectors.

Common applications include:

As chip line widths shrink, tolerance for airborne particles approaches zero. Cleanrooms ensure that every manufacturing step takes place in a precisely controlled environment.

Medicines, vaccines, and biological products require sterile or ultra-low-particle conditions to ensure purity, safety, and efficacy.

-

Aerospace and Precision Engineering

Optical components and aerospace parts cannot be exposed to contaminants, as surface particles may degrade performance.

High-standard food production and battery manufacturing both rely on environments with low particles, low ions, and minimal microbial presence.

These application scenarios demonstrate that cleanrooms are crucial for consistent quality and high reliability—areas where wonclean delivers specialized solutions.

What Materials Can Be Used in a Cleanroom?

To understand what materials can be used in a cleanroom, it is essential to consider the stringent requirements placed on cleanroom materials. They must be corrosion-resistant, easy to clean, non-particle-shedding, and exhibit low emissions. Therefore, material selection standards are much stricter than in conventional construction.

Common materials include:

-

Cleanroom wall panels and metal cladding, such as coated steel, stainless steel, or aluminum honeycomb panels.

-

Ceiling systems using aluminum frameworks and non-shedding surface materials to support filtration equipment.

-

Flooring materials, including epoxy, anti-static PVC, and conductive coatings that prevent static buildup and particle attraction.

-

HVAC and filtration system components, such as HEPA/ULPA filters, stainless steel ducts, and cleanroom-grade fan units.

-

Doors and windows, designed with airtight structures and easy-disinfection materials, often equipped with interlocks to maintain pressure balance.

Different cleanroom classes and industries require different material combinations. wonclean designs customized solutions based on the client’s process needs, budget, and facility layout.

Cleanroom Design Logic

When explaining what is a cleanroom, air management is central. However, a complete cleanroom setup integrates multiple systematic designs:

-

Airflow pattern planning, ensuring uniform distribution and minimizing turbulence or particle accumulation.

-

Personnel and material flow organization, using gowning rooms, buffer zones, and logistics channels to prevent cross-contamination.

-

Monitoring and alarm systems, providing real-time tracking of particles, temperature, humidity, pressure, and airflow.

-

Maintenance and operational strategies, including filter replacement cycles, pressure calibration, and equipment upkeep.

A cleanroom is not merely a physical space—it is an integrated environmental control system. The more stable the system, the more reliable the manufacturing process.

Why Cleanrooms Are the Foundation of Modern Manufacturing

At wonclean, our cleanroom solutions are engineered to meet the strictest international standards, including FDA, GMP, ISO and EMEA requirements. Beyond manufacturing cleanroom systems, we deliver complete turnkey services—from early-stage planning and feasibility evaluation to full design, construction, commissioning and final validation. Supported by an experienced in-house team of engineers, designers and technical specialists, we ensure that every cleanroom meets your precise operational needs.

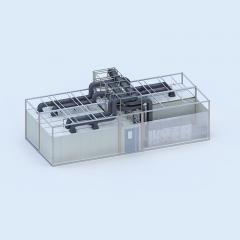

wonclean’s modular cleanrooms are built with fully prefabricated panels that integrate electrical wiring, lighting fixtures and essential utilities. This approach minimizes on-site disruption, shortens installation time and ensures consistent quality across every project. With our proven engineering methodology and long-term industry expertise, wonclean guarantees the performance, compliance and reliability of every cleanroom we deliver.

If your facility is preparing for a cleanroom project—whether in pharmaceuticals, microelectronics, or food laboratory applications—contact Wonclean. We provide fully integrated, end-to-end cleanroom services, ensuring your project is engineered, constructed, and validated with precision from concept to final delivery.

servicio en línea

servicio en línea