In the cleanroom industry, there is a common saying: “Air quality determines product quality.” And this is absolutely true. For any cleanroom, an hvac clean room system is far more than a device that delivers cooled or heated air—it is an integrated “air life-support system” responsible for particle control, pressure stability, airflow organization, and precise temperature and humidity uniformity.

If you’ve ever wondered how cleanroom air is actually “calculated”—what determines air changes, airflow volume, or cooling load—this article will walk you through the fundamental principles and help you understand these seemingly complex calculations in a clear, practical way.

Why is the HVAC System Considered the “Heart” of a Cleanroom?

If an HVAC system in a conventional building is a hardworking assistant, then the cleanroom HVAC system is a true “all-in-one protagonist.” A cleanroom does not passively receive conditioned air—it actively creates its own air environment.

The air must achieve:

-

Stable particle concentration

-

Tight temperature and humidity tolerance

-

Defined pressure direction (positive or negative)

-

Verifiable airflow patterns (unidirectional or non-unidirectional)

All of this depends on continuous filtration, dilution, and replacement of air. Every calculation in the HVAC design directly affects whether a cleanroom can meet its classification, operate stably, and avoid energy waste over years of operation.

As a cleanroom engineering company, Wonclean handles large volumes of design reviews every day and deeply understands the critical role of this system.

What is an Air Exchange?

For many newcomers, hearing “what is an air exchange” might sound like air simply “flowing around.” But in cleanroom engineering, the term has a very strict definition:

-

It refers to how many times the entire room’s air is replaced within a specific period.

The most common metric is ACH — Air Changes per Hour.

How is ACH calculated?

The formula is simple, as long as the units are consistent:

ACH = Total Supply Air Volume (m³/h) ÷ Room Volume (m³)

You might also wonder, “So is how to calculate air changes more complicated?”

Not really—but the ACH requirement depends on the cleanroom class:

-

ISO 8: 5–48 ACH

-

ISO 7: 60–90 ACH

-

ISO 6: 150–240 ACH

-

ISO 5: 240–480 ACH (though airflow velocity is the real control point here)

Higher ACH means faster contaminant removal, but also higher energy consumption. Reasonable—not excessive—air changes are the first principle of good design.

How is Supply Air Volume Calculated?

Once you know “how much air must be exchanged,” the next question is:

“How much air should actually be supplied?”

This directly relates to how do you calculate cfm for a room.

CFM = ACH × Room Volume (ft³) ÷ 60

If you want to convert ACH to airflow volume, that’s where the term air change per hour to cfm applies—ACH and CFM are fully convertible as long as the room volume is constant.

In cleanrooms, supply airflow is not determined only by air changes.

Sometimes cooling load becomes the dominant factor—meaning you may need more airflow for temperature reasons, even when air changes are already sufficient.

Airflow is Set—So How Do You Choose HVAC Tonnage?

Insufficient cooling capacity can make a cleanroom impossible to stabilize. This is why HVAC capacity (often called “tonnage”) must be accurately calculated.

Industry professionals frequently ask: “how to calculate hvac tonnage?”

Key components of cooling load include:

-

Equipment sensible heat

-

Occupant sensible and latent heat

-

Outdoor fresh air heat and moisture load

-

Heat gain from walls, ceilings, and solar load

-

Most importantly: Fan heat gain

Yes—cleanrooms require large airflow, and the fan power that moves this air becomes a major source of heat. This dramatically increases cooling load.

Therefore, tonnage calculations in cleanroom projects are much more complex than in typical commercial buildings and must consider airflow, supply air temperature difference, and fan heat simultaneously.

How do Fresh Air and Exhaust Air Maintain Pressure?

Cleanrooms maintain positive or negative pressure through the balance of:

-

Supply air

-

Return air

-

Exhaust air

For example:

-

Positive pressure: Supply > Exhaust

-

Negative pressure: Exhaust > Supply

This principle becomes even more critical in pharmaceutical environments, as described by hvac in relation to a pharmacy clean room, where strict pressure cascades prevent cross-contamination.

Fresh air calculation is based on:

-

Required fresh air for occupants

-

Compensation for local exhaust

-

Leakage needed to maintain pressure

-

Minimum code requirements

Exhaust air design focuses on equipment exhaust and pressure control.

How do Filter Efficiencies Affect Air Cleanliness?

A cleanroom’s final air cleanliness comes from its multi-stage filtration train:

-

Pre-filters (G4/F5): Capture large particles

-

Medium filters (F7–F9): Protect the HEPA filter

-

HEPA filters (H13/H14): The most critical stage

-

ULPA filters (U15+): For higher-class cleanrooms

The total efficiency is determined by:

Total penetration = Product of all stage penetrations

The formula looks simple, but design must consider pressure drop, lifespan, and airflow.

How is Airflow Velocity Verified in Unidirectional Flow Rooms?

High-grade cleanrooms such as ISO 5 often use a unidirectional (laminar) airflow system.

Common validation criteria include:

-

Average airflow velocity: 0.2–0.5 m/s (often 0.45 m/s ±20%)

-

Velocity uniformity test

-

Smoke visualization test

Air velocity is determined by:

Velocity = Supply Air Volume ÷ Effective Area

This is also the key difference between a clean room air conditioner and a typical comfort-cooling AC: a cleanroom HVAC system is designed not to “blow air” but to shape airflow.

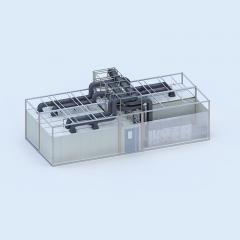

What does the Full System Look Like? (Design Workflow Overview)

A complete HVAC cleanroom design typically includes:

-

Define cleanliness class, temperature/humidity, pressure, and process needs

-

Select airflow pattern (unidirectional / non-unidirectional)

-

Determine air changes or airflow velocity

-

Calculate total supply airflow

-

Calculate cooling/heating load and determine HVAC tonnage

-

Determine fresh air and exhaust air volumes

-

Design duct system and airflow distribution

-

Verify equipment selection, static pressure, and system stability

Wonclean often uses CFD simulation and BIM coordination to ensure optimal airflow, equipment layout, and energy efficiency.

Conclusion

Whether you are researching clean room air conditioner, trying to understand air exchange, or exploring how do you calculate cfm for a room, this article aims to clarify one essential point:

A cleanroom HVAC system is a precise air-engineering ecosystem.

It integrates air changes, airflow volume, pressure control, filtration efficiency, cooling load, and airflow patterns—all of which form a tightly connected and highly engineered system.

For Wonclean, designing an hvac clean room isn’t about producing a few numbers. It’s about finding the most stable, energy-efficient, and reliable combination from thousands of parameters.

If you are planning a cleanroom project, reviewing an existing HVAC system, or need professional evaluation, feel free to reach out—we’re always glad to share our expertise.

servicio en línea

servicio en línea